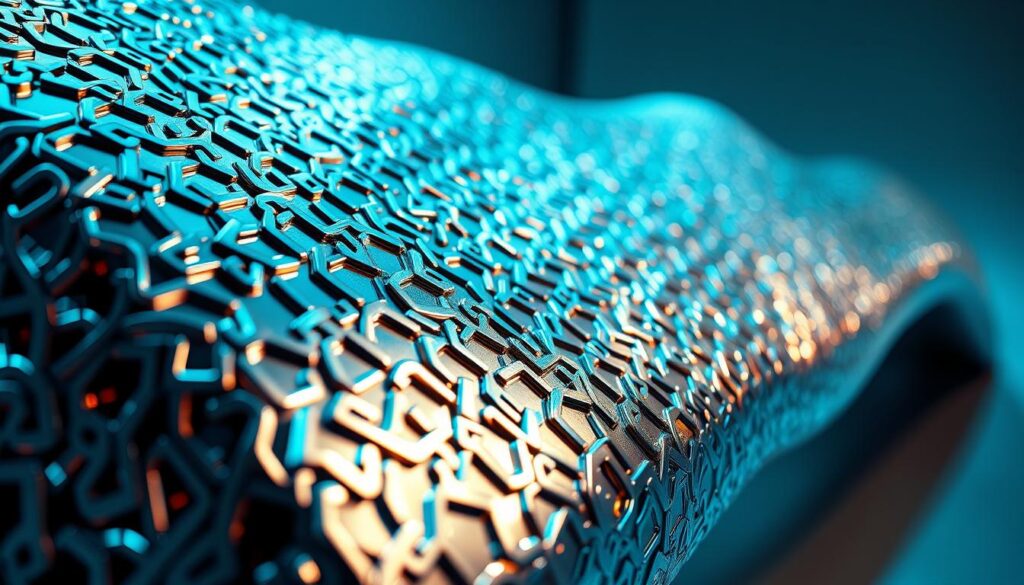

Shape Memory Metal is changing many industries with its amazing ability. It can remember and go back to its original shape after being bent. This makes it very useful in fields like aerospace and medicine, where smart materials are key.

This metal can handle very high temperatures and still return to its original shape. It’s getting a lot of attention for its potential to change how we design and make products.

Introduction to Shape Memory Metal

Shape Memory Metal is a special alloy used in many areas, from space to medical devices. Its unique qualities make it a valuable smart material.

Key Takeaways

- Shape Memory Metal is a type of smart materials that can remember its original shape.

- It has a wide range of applications across various industries, including aerospace and medical devices.

- Shape Memory Metal can withstand extreme temperatures and return to its original shape.

- It is a type of alloys with unique properties and characteristics.

- Shape Memory Metal is gaining attention worldwide for its potential to transform product design and engineering using smart materials and alloys.

- Its properties make it a valuable material in the world of smart materials and alloys.

What Is Shape Memory Metal?

Shape memory metal is a special material that can go back to its original shape when heated or cooled. This shape memory effect happens because of its unique structure. This structure changes with temperature changes. The properties of this metal make it perfect for many uses.

The shape memory effect comes from a complex process. It involves the material’s structure changing with temperature. This lets the material “remember” its original shape and return to it after being deformed. The properties of this metal, like its high temperature resistance and corrosion resistance, make it very valuable.

Shape memory metal has some key features. It can recover its original shape, resist corrosion well, and handle high temperatures. These properties make it great for many uses, from medical devices to aerospace engineering.

Basic Properties and Characteristics

- High corrosion resistance

- Ability to withstand high temperatures

- Ability to recover its original shape

How Shape Memory Effect Works

The shape memory effect is a complex process. It involves the material’s structure changing with temperature. This lets the material “remember” its original shape and return to it after being deformed.

The History Behind Shape Memory Metals

The discovery of it started in the 1960s. This was the beginning of its development as a special material. Knowing its history helps us understand how it was made and what’s next.

Some important moments in it’s history are:

- William J. Buehler found the first Shape Memory Alloy.

- Scientists worked on different types of Shape Memory Alloys.

- They explored its unique features and uses.

The journey of it’s development is rooted in its history. From its first discovery to now, it’s been a path of discovery. As research finds new uses, it’s future is bright.

Understanding the Science of Shape Memory Alloys

Shape Memory Alloys have special properties. They can change shape in response to temperature or stress. This happens because of their unique crystalline structure.

This structure can change and then go back to its original shape. By studying this, scientists can make new Shape Memory Alloys with better properties.

Changes in the alloy’s crystalline structure are key. When heated or cooled, the crystal lattice changes. This lets the alloy change shape and then go back to its original form.

Crystalline Structure Changes

The structure of Shape Memory Alloys is made of atoms arranged in a lattice. This lattice can change shape with temperature or stress changes. This is what lets the alloy change and then return to its original shape.

Temperature-Induced Transformations

When the alloy is heated or cooled, its structure changes. This change lets the alloy change shape. Then, when the temperature changes again, it returns to its original shape.

Key Properties of Shape Memory Metal

Shape Memory Metal is a special material with many key properties. It’s strong, resistant to corrosion, and safe for the body. These characteristics make it stand out from other materials.

Some of the notable key properties of it include:

- High strength and durability

- Corrosion resistance in harsh environments

- Biocompatibility for medical applications

- Ability to withstand extreme temperatures

- High ductility for flexibility and reliability

Knowing these characteristics is key for designers and engineers. They can pick the right Shape Memory Alloy for their projects. This way, industries can create new solutions that use it’s unique features.

Common Applications in Modern Industry

Shape Memory Metal is used in many applications across different industries. It shows its versatility and potential. This material is valuable in fields like aerospace and consumer electronics.

In various industries, itl helps create new products and solutions. Here are some examples:

- Aerospace: used in actuators and sensors because of its strength and resistance to fatigue

- Medical devices: used in implants and surgical tools because it’s safe and durable

- Consumer electronics: used in antennas and connectors

- Automotive: used in valve actuators and exhaust systems because of its high temperature resistance

These applications show how it can change many industries. It offers unique properties that make it key for future growth and innovation.

Benefits and Advantages in Engineering

Shape Memory Metal has many benefits in engineering. It’s great for creating new designs. This metal can change shape and return to its original form. This makes it very useful for many projects.

Here are some key benefits of using it in engineering:

- Design flexibility: it can be shaped to fit specific needs. This makes it perfect for many uses.

- Energy efficiency: It can change shape without needing extra energy. This saves energy and is good for the environment.

- Durability: It doesn’t corrode or get tired easily. This means it lasts a long time in tough conditions.

Shape Memory Metal is a top choice for engineers. It offers flexibility, saves energy, and lasts long. Using it in designs leads to better, more efficient solutions. This benefits many areas of engineering.

The benefits of it in engineering are clear. Its unique properties make it great for many projects. As engineers keep finding new uses, it will play a big role in engineering’s growth and innovation.

Challenges and Limitations

Shape Memory Metal has many benefits, but it also faces challenges and limitations. One big issue is its high cost. This makes it hard for many to use it widely.

Some of the main challenges and limitations of it are:

- High cost: Making it is complex and expensive. This makes it hard for companies to use it.

- Limited availability: Some Shape Memory Alloys are hard to find. This limits their use in certain areas.

- Sensitivity to temperature and stress: The material’s properties can change with temperature and stress. This requires special handling and design.

It’s important for researchers and engineers to understand these challenges. They need to find ways to solve these problems. This will help unlock it’s full potential.

By tackling these challenges, we can use Shape Memory Metal in more areas. This will drive innovation and growth in different industries.

Future Innovations and Possibilities

The future of Shape Memory Metal is full of innovations and technologies. New materials and engineering advances are on the horizon. These will bring new Shape Memory Alloys with better properties.

Some exciting areas of development include:

- Emerging technologies like 3D printing and nanotechnology

- Research developments in self-healing materials and soft robotics

- Potential new applications in aerospace and medicine

As these innovations and technologies grow, Shape Memory Metal will become more crucial. It will shape the future of many industries.

Conclusion

Shape memory metal is truly amazing. It can change and adapt in ways we never thought possible. This makes it a game-changer in engineering and innovation.

As we look to the future, we’ll see even more progress in this field. New alloys and ways to make them will open up more possibilities. Shape memory metal will keep changing the game in fields like aerospace, medicine, and tech.

With shape memory metal, the sky’s the limit. It’s a key tool for making things better, stronger, and more flexible. The future is bright for this incredible material, and it’s ready to make a big impact.

FAQ

What is Shape Memory Metal?

Shape Memory Metal, also known as smart materials, is a special alloy. It can remember and return to its original shape after being bent. This makes it very useful in many industries.

How does the Shape Memory Effect work?

The shape memory effect lets the material go back to its original shape when heated or cooled. This happens because of its unique structure, which changes with temperature.

What are the key properties of Shape Memory Metal?

Shape Memory Metal is strong, resistant to corrosion, and safe for the body. It can handle very high temperatures. It’s also very flexible, making it great for many uses.

Where is Shape Memory Metal used in modern industry?

It’s used in many fields. In aerospace for things like actuators and sensors. In medicine for implants and tools. It’s also in electronics and cars.

What are the benefits of using Shape Memory Metal in engineering?

Using it in engineering brings many advantages. It’s flexible in design, saves energy, and lasts longer. Its ability to return to its original shape makes it very reliable.

What are the challenges and limitations of Shape Memory Metal?

There are some downsides. It’s expensive, hard to find, and sensitive to temperature and stress. This means it needs special care and design.

What are the future innovations and possibilities for Shape Memory Metal?

The future looks bright. New technologies and research are creating better alloys. It could lead to self-healing materials and soft robotics, opening up new uses.

Source link

- https://en.wikipedia.org/wiki/Shape-memory_alloy

- https://www.wired.com/story/shape-memory-alloys

- https://www.xotmetals.com/blog/aerospace-applications-of-shape-memory-alloyssmas/

- https://en.wikipedia.org/wiki/Magnetic_shape-memory_alloy

- https://www.wired.com/story/how-nasa-tests-shapeshifting-plane-wings